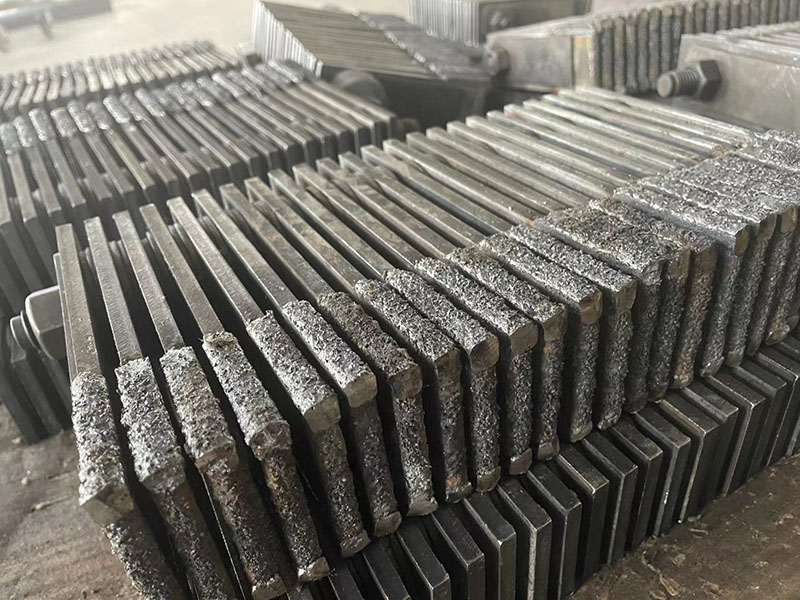

Tungsten Carbide Overlay Welding Hammer Blade

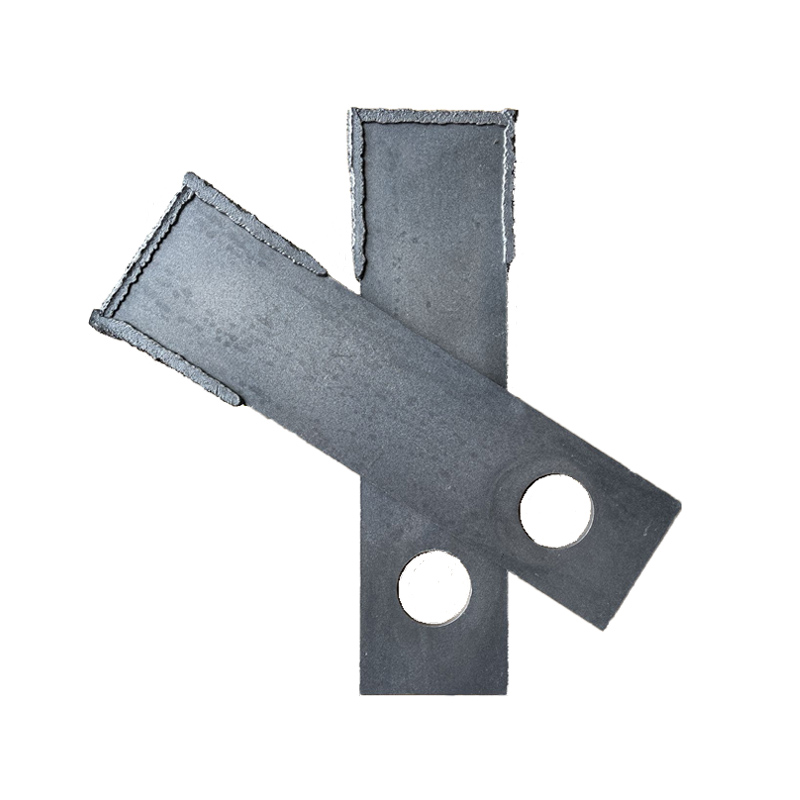

1. Sebopeho:Mofuta oa lesoba le nang le hlooho e le 'ngoe, mofuta oa lesoba le nang le lihlooho tse peli

2. Boholo:Mefuta e fapaneng ea boholo, e hlophisitsoeng

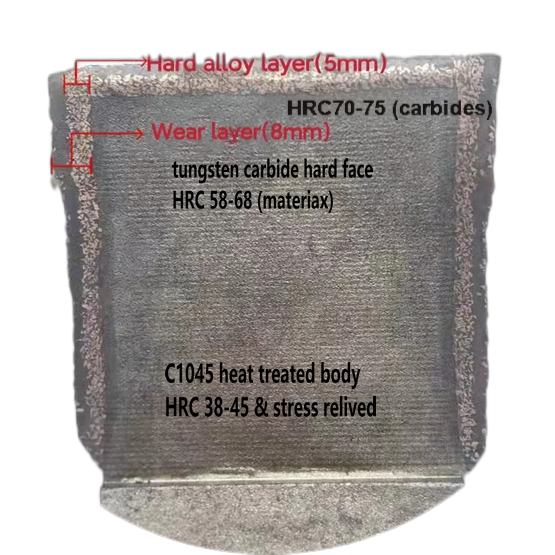

3. Boitsebiso:Litšepe tsa boleng bo holimo tse hananang le ho roala, terata ea ho chesella e sa cheseheng, likaroloana tsa tungsten carbide

4. Ho thatafala:

HRC70-75 (tungsten carbide layer)

Sefahleho se thata sa welding - HRC 55-63 (lera le sa keneng)

'Mele oa Hammer - HRC 38-45 le Khatello ea Maikutlo

Ho potoloha sekoti: HRC38-45 (bothata bo ka etsoa ho latela litlhoko tsa bareki)

5. Karolo e le 'ngoe ea lehare la hamore:Bophahamo ba tungsten carbide layer bo fihla ho 3mm-4mm.

Bophahamo ba ho hanyetsa ka kakaretso bo fihla ho 6mm-8mm. Bophelo ba eona ba tšebeletso bo habeli ho feta ba lihlahisoa tse tšoanang. E ka fokotsa litšenyehelo tsa ho senya ka hoo e ka bang 50% le ho boloka nako e ncha.

6. Karolo e 'meli ea lehare la hamore:Bophahamo ba lera la carbide la tungsten bo fihla ho 6mm-8mm, 'me bophahamo ba ho hanyetsa ka kakaretso bo fihla ho 10mm-12mm, e nang le melemo e ke keng ea bapisoa.

1. Bophahamo ba sekoahelo sa weld overlay se fihla ho 3mm-4mm, 'me kakaretso ea ho hanyetsa ho apara e fihla ho 6mm-8mm. Kakaretso ea ho hanyetsa ho apara lihlahisoa tse ling tse tšoanang 'marakeng ke 3mm-4mm feela.

2. Ho na le palo e kholo ea likaroloana tsa tungsten carbide sebakeng sa welding, e leng se etsang hore sehlahisoa se se ke sa apara. Ha ho na likaroloana tsa tungsten carbide lihlahisoa tse ling tse tšoanang 'marakeng.

Lehare la HMT'hamore

'Maraka oa hamore

1. Ho thatafala ho phahameng le ho hanyetsa ho apara:Lihamore tsa Tungsten carbide li na le boima bo phahameng ka ho fetisisa 'me li ka boloka ho thatafala ha holim'a metsi ka nako e telele sebakeng sa likhohlano le ho apara, ka tsela eo li lelefatsa bophelo ba lisebelisoa, ho fokotsa nako ea ho theoha le litšenyehelo tsa tlhokomelo.

2. Corrosion resistance:Lihamore tsa Tungsten carbide li sebetsa hantle libakeng tse senyang tse kang mongobo, asiti le alkali, 'me li ka sebelisoa nako e telele libakeng tsena ntle le ho senyeha kapa ho senyeha. Li loketse lisebelisoa le likarolo tsa meralo mafapheng a kang a leoatle, tlhoekiso ea metsi le boenjiniere ba lik'hemik'hale.

3. Ho hanyetsa mocheso o phahameng:Tungsten carbide e ka boloka ts'ebetso e tsitsitseng maemong a mocheso o phahameng ntle le ho nolofatsa kapa ho qhibiliha. Sena se etsa hore e be le karolo ea bohlokoa lits'ebetsong tsa mocheso o phahameng joalo ka merafo, metallurgy le petroleum.

4. Tšusumetso ea ho hanyetsa:Lihamore tsa Tungsten carbide li na le boima bo botle le ho hanyetsa tšusumetso, tse loketseng lisebelisoa le likarolo tsa mohaho tlas'a mojaro o phahameng le maemo a boima ba tšusumetso, joalo ka lisebelisoa tsa mechine, likoloi le likoloi tsa lipalangoang indastering ea merafo le ea kaho.

Re ka fana ka lehare le khethehileng la tungsten carbide hamore. Bophelo ba ts'ebeletso bo habeli ho feta ba lihlahisoa tse ling tse tšoanang, tse ka fokotsang litšenyehelo tsa ho senya ka hoo e ka bang 50% -60% le ho boloka nako ea ho nkela mahare a hamore sebaka.

Tungsten carbide hamore blade, Tungsten carbide hardness HRC70-75, hard surface hardness HRC55-63 (wear-resistant layer) bakeng sa ho tjheseletsa ho hodimo. Ka mor'a ho sila, Ha e boloke feela bohale ba ho itšeha ha lehare la hamore, empa hape e ntlafatsa ho hanyetsa ha lehare la hamore.

1. Mofuta o tloaelehileng- welded qetellong e 'ngoe, theko e tlaase

2. Mofuta o nang le lihlooho tse peli- e sebelisitsoe habeli, ho boloka litšenyehelo tsa tšebeliso

3. Mofuta o atolositsoeng oa lehlakore- bolelele ba lera la welding mahlakoreng ka bobeli bo atolosoa ho 90MM

4. Mofuta oa ho kuta- Ka mor'a ho sila lera la welding, ho thehoa moeli oa ho itšeha, o nang le ts'ebetso e ntle ea ho kuta

5. Mofuta o mosesaane haholo- e ka cheselletsa lehare la hamore le lesesaane ka ho fetesisa, le nang le botenya ba 3MM feela

6. Mofuta oa lera habeli- Theknoloji ea welding ea mekhahlelo e 'meli, e nang le khanyetso ea ho roala habeli

7. Tungsten carbide blade ea 'moba shredder seha