Lihlahisoa

-

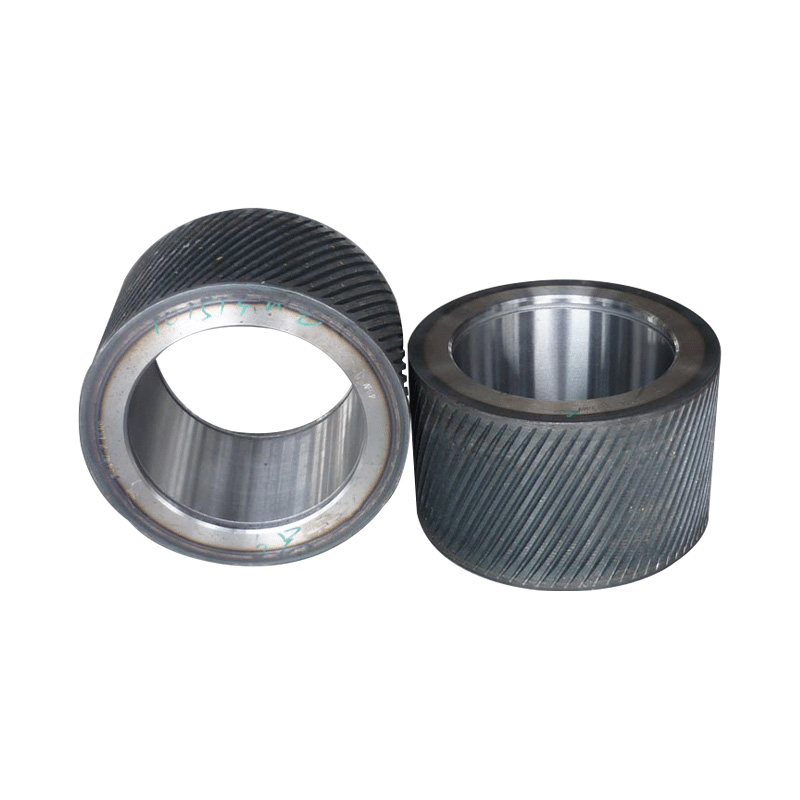

Shell ea Leino la Hole

Li-dimples tse nyane tse holim'a khetla ea rolara li thusa ho ntlafatsa ts'ebetso ea "pelletizing" ka ho fokotsa likhohlano lipakeng tsa rolara le thepa e hatelletsoeng.

-

Kopano ea Roller Shell bakeng sa Mochini oa Pellet

Kopano ea li-roller ke karolo ea bohlokoa ea mochine oa leloala la pellet, kaha o fana ka khatello le matla a ho kuta lihlahisoa tse tala, ho li fetola li-pellets tsa junifomo tse nang le boima bo tsitsitseng le boholo.

-

Shell ea Sawdust Roller

Moralo o kang oa sawtooth oa khetla ea rolara o thusa ho thibela ho thella lipakeng tsa rolara le thepa e tala. Sena se tiisa hore thepa e hatelloa ka ho lekana, e fellang ka boleng bo tsitsitseng ba pellet.

-

Lekhetla la Cross meno Roller

● Boitsebiso: boleng bo phahameng le tšepe e sa tsitsang;

● Ho thatafatsa le ho futhumatsa: etsa bonnete ba ho tšoarella ho hoholo;

● Likhetla tsohle tsa rona li phethoa ke basebetsi ba nang le tsebo;

● Ho thatafala ha likhetla tsa rolara ho tla lekoa pele ho pepa. -

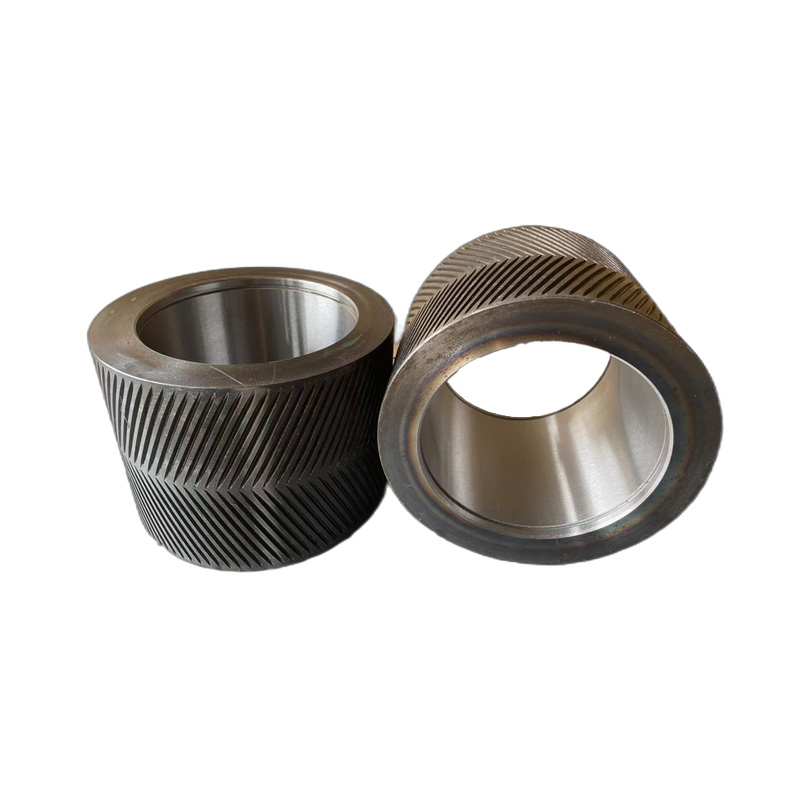

Helical Teeth Roller Shell

Likhetla tsa helical teeth roller li sebelisoa haholo-holo tlhahisong ea li-aquafeeds. Sena se bakoa ke hore likhetla tsa lirolara tse nang le likarolo tse koetsoeng li fokotsa ho thella ha lintho nakong ea extrusion 'me li hanela tšenyo e bakoang ke ho otla ha hamore.

-

Stainless Steel Roller Shell E Nang le Lipheletso Tse Bulehileng

Khetla ea roller e entsoe ka X46Cr13, e nang le boima bo matla le ho hanyetsa ho roala.

-

Y Model Meno Roller Shell

Meno a na le sebopeho sa Y mme a arotsoe ka ho lekana holim'a khetla ea rolara. E nolofalletsa lisebelisoa ho hatelloa ho tloha bohareng ho ea mahlakoreng a 2, ho eketsa katleho.

-

Tungsten Carbide Roller Shell

Bokaholimo ba khetla ea rolara bo cheselitsoe ka tungsten carbide, 'me botenya ba tungsten carbide layer bo fihla ho 3MM-5MM. Ka mor'a phekolo ea mocheso oa bobeli, khetla ea rolara e na le boima bo matla haholo le ho hanyetsa ho apara.

-

Shell ea meno a mabeli

Re sebelisa tšepe ea boleng bo holimo ho etsa khetla e 'ngoe le e 'ngoe ea pellet mill roller ka mokhoa o nepahetseng haholo bakeng sa boholo bofe kapa bofe le mofuta oa leloala la pellet' marakeng.

-

Circle Teeth Roller Shell

Khetla ena ea rolara e na le bokaholimo bo kobehileng, bo nang le masenke. Li-corrugations li ajoa ka ho lekana holim'a khetla ea rolara. Sena se nolofalletsa boitsebiso hore bo be bo leka-lekaneng le hore ho be le phello e ntle ka ho fetisisa ea ho tsoa.

-

3MM Hammer Blade

HAMMTECH e fana ka li-hamore tsa boleng bo holimo tse ka khonehang tsa 3mm bakeng sa mefuta e fapaneng. Litlhaloso tse fapaneng li teng ho fihlela tlhoko ea hau.

-

Roller Shell Shaft ea Pellet Mill

● Ho mamella meroalo

● Fokotsa likhohlano le ho khathala

● Fana ka tšehetso e lekaneng bakeng sa likhetla tsa lirolara

● Eketsa botsitso ba mekhoa ea mechine