Bophelo ba tšebeletso ealehare la hamoree amana le thepa ea lehare la hamore ka boeona, mofuta oa thepa e sithabetseng, joalo-joalo Thepa ea lehare la hamore ke ntho ea bohlokoa ka ho fetisisa e amang nako ea eona ea bophelo. Maqhubu a hamore 'marakeng a batla a arotsoe ka mekhahlelo e meraro: likhaba tse tloaelehileng tsa hamore, li-hamore tsa tungsten carbide tse cheselitsoeng, le lihamore tsa tungsten carbide fusion tse cheselitsoeng.

Har'a bona, hafeela karoloana e tloaelehileng ea hamore e le sekoahelo sa hamore se nang le mocheso, kapa ho sebelisoa hamore ea tšepe ea 65Mn feela, theko ea mofuta ona oa hamore e batla e le theko e tlaase, empa bophelo ba tšebeletso bo lumellanang le bona bo khutšoanyane.

Lihamore tsa ho tjheseletsa tsa tungsten carbide spray li sebelisoa haholo 'marakeng, li sebelisa theknoloji ea welding ea oxyacetylene ho fafatsa phofo ea weld tungsten carbide holim'a substrate ea hamore, ebe mocheso o tšoara hamore ho hlahisa sehlahisoa sa ho qetela. Leha ho le joalo, ka lebaka la tikoloho e thata ea tlhahiso le tšusumetso ea boleng ba terata ea tungsten carbide, boleng ba hamore ea ho qetela ea tungsten carbide le eona ha e lekane, hangata e tsamaisana le likoli tse kang li-pores le li-inclusions tsa weld layer, tse amang bophelo ba tšebeletso ea eona ka botebo. Haholo-holo ha lisebelisoa tse thata hanyenyane li robehile, ho bonolo ho etsa hore lesela la weld le oe. Ho phaella moo, ts'ebetso ea tlhahiso e tsamaisana le lerōle le leholo le likhase tse kotsi, tse ke keng tsa finyella boiketsetso, 'me litebello ha li tšepise haholo.

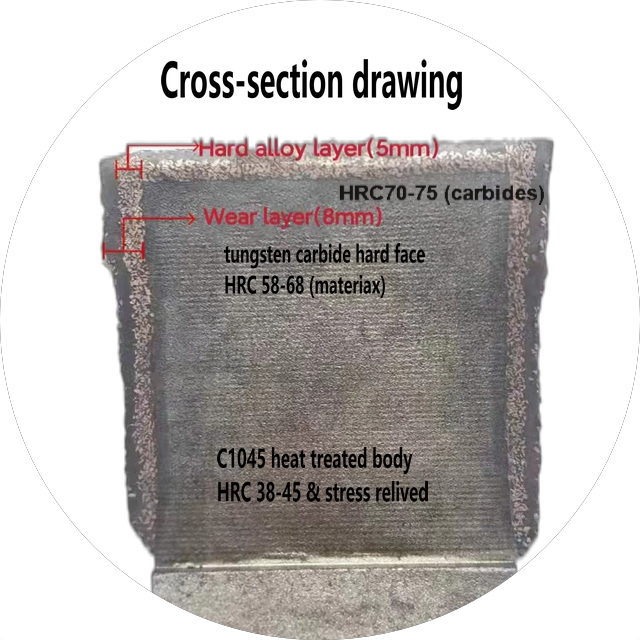

Lihamore tsa HMT's tungsten carbide fusion welding li sebelisa theknoloji ea plasma welding cladding, e behang karolo ea likaroloana tse thata tsa alloy holim'a substrate ea hamore, e fihlelang botenya bo lekanang pakeng tsa substrate ea hamore le lera le thata la alloy welding. Ka nako e ts'oanang, karolo e 'ngoe le e' ngoe e thata ea alloy e na le mekhoa e mengata ea ho itšeha, e ntlafatsang haholo ts'ebetso ea ho kuta ea hamore. HMT's hard alloy fusion welded hamore likotoana li na le ts'ebetso e ntle haholo, e nang le khanyetso e phahameng ea ho roala, bophelo ba ts'ebeletso, khanyetso ea tšusumetso, le ts'ebetso e mpe e bapisoang le likotoana tsa hamore tse cheselitsoeng tsa tungsten carbide. Ho feta moo, ts'ebetso ea tlhahiso e ka ba e ikemetseng le e nang le botsoalle ba tikoloho, e etsa hore e be mokhoa oa ho hlahisa likotoana tsa hamore tsa morao-rao.

Ho sithabela ha thepa ho boetse ho na le phello e kholo bophelong ba ts'ebeletso ea lihamore, 'me ho sebelisa lihamore tse fapaneng ho pshatla lisebelisoa tse fapaneng ho ka ntlafatsa haholo ts'ebetso ea ho senya. Lisebelisoa tse ling li na le boima bo phahameng, kahoo tšusumetso ea hamore le eona e matla haholo. Mohlala, ha sejo sa bamboo le hamore ea ho cheselletsa setlolo sa tungsten carbide se robeha, lesela la weld le ka heleha. Bakeng sa lisebelisoa tse nang le moaparo oa bohlokoa, bolelele ba lesela le sa sebetseng le lokela ho eketsoa ka 100mm, joalo ka phepelo ea lekhapetla la lijo-thollo. Ho boetse ho na le sehlopha sa li-block tsa patsi tse pshatlehileng, tse nang le tšusumetso e matla le ho roala, 'me lihamore tsa tungsten carbide spray li ke ke tsa sebelisoa ho hang. Bakeng sa lihamore tse tloaelehileng, bophelo ba bona ba tšebeletso bo batla bo le bokhutšoanyane. Bakeng sa ho silakanya lisebelisoa tse joalo, lihamore tsa HMT tse thata tsa alloy fusion li ka fihlela litlhoko hantle haholo. Ka mor'a tšebeliso e sebetsang ea moetsi oa li-blocks tsa lehong tse pshatlehileng, ho pakiloe hore lihamore tsa HMT tse thata tsa alloy fusion li ka fihlela litlhoko hantle haholo. Ho phaella moo, mongobo oa poone o boetse o na le phello e kholo ho ts'ebetsong ea ho senya. Ha mongobo o phahame, ho roala ha hamore ho batla ho le kholo 'me bophelo ba tšebeletso bo khutšoanyane.

Nako ea poso: Apr-02-2025