Indasteri ea granulation, ebang ke mochini o bataletseng oa pellet kapa mochini oa ring die pellet, molao-motheo oa eona oa ts'ebetso ke ho itšetleha ka motsamao o lekanyelitsoeng lipakeng tsa rollershell ea khatello le hlobo ho tšoara thepa le ho kenya seteisheneng se sebetsang, ho e ntša ka sebopeho, ebe o e khaola ka likaroloana tsa bolelele bo hlokahalang ka lehare la ho itšeha.

Khetla ea li-roller tsa li-particle

Khetla ea rolara ea khatello haholo-holo e kenyelletsa shaft ea eccentric, li-bearings, khetla ea rolara ea khatello e kentsoeng ka ntle ho moqomo oa khatello, le likarolo tse sebelisoang ho tšehetsa le ho lokisa khetla ea rolara ea khatello.

The rollershell khatello e petetsa thepa ka mokoting hlobo 'me e etsa tlas'a khatello ka lesoba hlobo. E le ho thibela khatello ea khatello hore e se ke ea thella le ho eketsa matla a ho tšoara, ho tlameha ho ba le matla a itseng a khohlano pakeng tsa mochine oa khatello le thepa. Ka hona, mehato ea ho eketsa likhohlano le ho apara ho hanyetsa hangata e nkoa ka holim'a khatello ea khatello. Ha mekhoa ea sebopeho sa mochine oa khatello le hlobo e ikemiselitsoe, sebopeho sa sebopeho le boholo ba bokantle ba ka ntle ba khatello ea khatello li na le tšusumetso e kholo ho katleho ea granulation le boleng ba likaroloana.

Sebopeho sa bokaholimo ba khetla ea rolara ea khatello

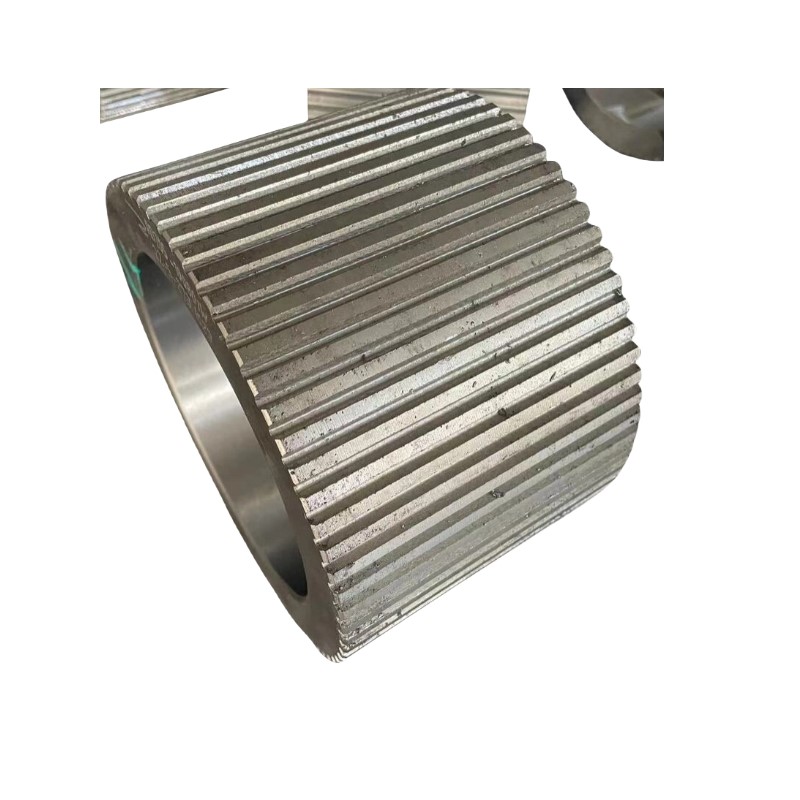

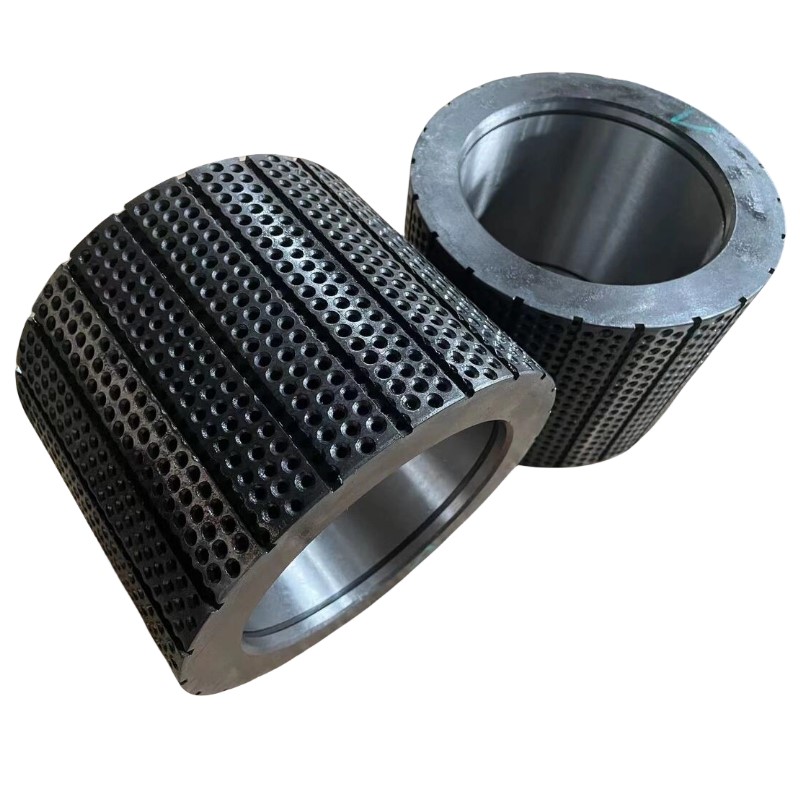

Ho na le mefuta e meraro e tloaelehileng ea bokaholimo bakeng sa lirolara tse seng li ntse li le teng: rolara e kolobisitsoeng, bokaholimo bo koetsoeng bo nang le tiiso e tiileng, le bokaholimo ba khekhe ea linotsi.

The toothed groove type pressure roller e na le ts'ebetso e ntle ea ho bilika 'me e sebelisoa haholo lifemeng tsa phepelo ea liphoofolo le likhoho. Leha ho le joalo, ka lebaka la ho thellela ha lijo ka har'a groove ea meno, ho roala ha mochini oa khatello le hlobo ea lesale ha ho tšoane haholo, 'me ho roala lipheletsong tse peli tsa rolara ea khatello le hlobo e matla haholo.

The toothed groove mofuta oa khatello ea rolara e nang le tiiso e ka thōko e loketse haholo-holo bakeng sa tlhahiso ea lisebelisoa tsa metsing. Lisebelisoa tsa metsing li tloaetse ho thella nakong ea extrusion. Ka lebaka la ho tiisa ka mahlakoreng ka bobeli a groove e nang le meno, ha ho bonolo ho thellela mahlakoreng ka bobeli nakong ea phepelo ea phepelo, e bakang phepelo e ts'oanang haholoanyane. Ho roala ha khatello ea khatello le hlobo ea lesale le tsona li tšoana haholo, e leng se etsang hore ho be le bolelele bo tsitsitseng ba li-pellets tse hlahisoang.

Molemo oa rolara ea khekhe ea linotsi ke hore ho apara hlobo ea lesale ho tšoana, 'me bolelele ba likaroloana tse hlahisoang le bona bo batla bo tšoana. Leha ho le joalo, ts'ebetso ea coil e fokola, e amang tlhahiso ea granulator 'me ha e tloaelehe joaloka tšebeliso ea mofuta oa slot tlhahiso ea sebele.

Se latelang ke kakaretso ea mefuta e 10 ea lirolara tsa khatello ea mochini oa likaroloana bakeng sa hlobo ea lesale la khatello ea Baoshell, 'me tse 3 tsa ho qetela ehlile ke tseo u so li boneng!

NO.10 Mofuta oa Groove

NO.9 Mofuta oa groove o koetsoeng

NO.8 Mofuta oa khekhe ea linotsi

NO.7 Taemane e bopehileng

NO.6 E sekametseng groove

NO.5 Groove+honeycomb

NO.4 Koala groove+mahe a linotsi

NO.3 Incred groove+honeycomb

NO.2 Lesapo la tlhapi le phunya

NO.1 ripple e bōpehileng joaloka arc

SEPPPECIAL MODEL: TUNGSTEN CARBIDE COLLER SHELL

Mokhoa oa kalafo bakeng sa ho thella ha mochini o hatellang oa mochini

Ka lebaka la tikoloho e thata ea ho sebetsa, matla a holimo a ho sebetsa, le sekhahla sa ho roala ka potlako sa khetla ea khatello ea khatello, "rolara ea khatello ke karolo e tlokotsing ea mochini oa likaroloana 'me e hloka ho nkeloa sebaka khafetsa. Ts'ebetso ea tlhahiso e bonts'itse hore hafeela litšoaneleho tsa lisebelisoa tsa tlhahiso li fetoha kapa maemo a mang a fetoha nakong ea ts'ebetso, ts'ebetso ea ho thella ha khatello ea mochini oa likaroloana e ka etsahala. Haeba ho na le ho thella ha rolara ea khatello nakong ea ts'ebetso ea granulation, ka kopo u se ke oa tšoha. Bakeng sa lintlha tse qaqileng, ka kopo sheba mekhoa e latelang:

Lebaka la 1: Ho se tsepamise maikutlo ho fokolang ha mochini oa khatello le ho kenngoa ha spindle

Tharollo:

Sheba hore na ho kenngoa ha li-bearings tsa khatello ea khatello hoa utloahala ho qoba ho etsa hore khetla ea khatello ea khatello e khelohe ka lehlakoreng le leng.

Lebaka la 2: Molomo oa tšepe oa hlobo o fatše o bataletse, o etsa hore hlobo e se ke ea ja thepa

Tharollo:

Sheba hore na li-clamp li sebetsa joang, mabili a phetiso, le mehele ea granulator.

Fetola botebo ba ho kenya hlobo ea selikalikoe, ka phoso e sa feteng 0.3mm.

Lekhalo pakeng tsa li-roller tsa khatello le lokela ho fetoloa ho: halofo ea sebaka se sebetsang sa li-roller tsa khatello e sebetsa le hlobo, 'me lebili la ho lokisa lekhalo le sekoti sa ho koala le tsona li lokela ho netefatsoa hore li sebetsa hantle.

Ha "rolara ea khatello e thellang, u se ke ua lumella mochini oa likaroloana hore o se ke oa sebetsa nako e telele 'me u emetse hore o ntše lisebelisoa ka bohona.

The compression karo-karolelano ea lesale hlobo aperture sebelisoa e phahameng haholo, e leng se etsa hore lintho tse phahameng ho ntša khanyetso ea hlobo 'me e boetse ke e' ngoe ea mabaka a ho thella ha rolara khatello.

Mochini oa pellet ha oa lokela ho lumelloa ho sebetsa ho sa hlokahale ntle le ho fepa lintho tse bonahalang.

Lebaka la 3: Therola ea khatello e tsitsitse

Tharollo:

Nka sebaka libere rolara khatello.

Lebaka la 4: Khaketla ea roller ea khatello ha e pota-potile

Tharollo:

Boleng ba khetla ea rolara ha bo tšoanelehe, nka sebaka kapa u lokise khetla ea rolara.

Ha "rolara ea khatello e thellang, e lokela ho emisoa ka nako e nepahetseng ho qoba likhohlano tsa nako e telele tse sa sebetseng tsa roller ea khatello.

Lebaka la 5: Ho kobeha kapa ho hlephisa ha spindle ea khatello

Tharollo:

Tlosa kapa u tiise spindle, 'me u hlahlobe boemo ba seluloana sa khatello ha u nkela hlobo ea selikalikoe le rolara ea khatello.

Lebaka la 6: Sebaka sa ho sebetsa sa rolara ea khatello e batla e sa lumellane le sebaka se sebetsang sa hlobo ea lesale (ho tšela moeli)

Tharollo:

Hlahloba hore na mochine oa khatello o kenngoa ka mokhoa o sa lokelang ebe o o nkela sebaka.

Sheba hore na eccentric shaft ea rolara ea khatello e holofetse.

Sheba hore na ho na le ho apara ha li-bearings tse ka sehloohong tsa shaft kapa lihlahla tsa mochine oa likaroloana.

Lebaka la 7: Sehlahisoa sa spindle sa granulator se seholo haholo

Tharollo:

Sheba ho tiisa ho hlaka ha granulator.

Lebaka la 8: Sekhahla sa ho otla ha hlobo ea selikalikoe se tlase (tlase ho 98%).

Tharollo:

Sebelisa mochini oa sethunya ho phunya lesoba la hlobo, kapa u e belise ka oli, u e sile pele u fepa.

Lebaka la 9: Lisebelisoa tse tala li mahoashe haholo 'me li na le mongobo o phahameng

Tharollo:

Ela hloko ho boloka mongobo o ka bang 15%. Haeba mongobo oa thepa e tala o phahame haholo, ho tla ba le ho thibela hlobo le ho thella ka mor'a hore lihlahisoa tse tala li kene ka har'a hlobo. Sebaka sa taolo ea mongobo oa lisebelisoa tse tala ke pakeng tsa 13-20%.

Lebaka la 10: Ho fepa hlobo e ncha kapele haholo

Tharollo:

Fetola lebelo ho etsa bonnete ba hore rolara ea khatello e na le ts'ebetso e lekaneng, thibela roller ea khatello hore e se ke ea thella, 'me hang-hang hlahloba ho apara hlobo ea lesale le rolara ea khatello.

Nako ea poso: Mar-25-2024