Ha ho bapisoa le tšepe e tloaelehileng ea manganese kapa tšepe ea sesebelisoa, lihamore tsa tungsten carbide li na le melemo e mengata ea ho hanyetsa le bophelo ba tšebeletso. Leha tšepe ea manganese kapa tšepe ea sesebelisoa le eona e na le khanyetso e itseng, lehare la tungsten carbide hammer mill le na le boima bo phahameng le ho hanyetsa ho matla ho hoholo, haholo ha le sebetsana le lisebelisoa tse thata.

Tungsten carbide hammer thipa crusher e sebelisoa haholo bakeng sa ho silakanya mahoashe le mahareng a lisebelisoa tse fapaneng ka matla a hatellang ka tlase ho 320 megapascals. E na le karo-karolelano e kholo ea ho pshatla, ts'ebetso e bonolo, ho ikamahanya le maemo ho mefuta e fapaneng ea lisebelisoa, le matla a matla a ho sithabela, 'me e nka karolo e kholo tšimong ea lisebelisoa tse silakanyang. Hammer thipa crusher e loketse ho pshatla lisebelisoa le liminerale tse fapaneng, 'me e se e sebelisoa haholo liindastering tse fapaneng tse kang lisebelisoa tsa elektroniki, meriana, ceramics, polycrystalline silicon, aerospace, optical glass, libeteri, libeteri tse tharo tsa phofshoana ea phofshoana, matla a macha, keketso ea tšepe, mashala, ore, indasteri ea lik'hemik'hale, lisebelisoa tsa mohaho, geology, le ho fetola mochine, joalo-joalo. boholo ba likaroloana ho fihlela litlhoko tse fapaneng tsa basebelisi ba fapaneng ba li-crusher. Li-crusher tsa thipa tsa hamore li itšetlehile haholo ka tšusumetso ho pshatla lisebelisoa. Ts'ebetso ea ho senya e batla e le ka tsela e latelang: thepa e kena ka har'a sekontiri 'me e sithabetsoa ke tšusumetso ea hlooho ea hamore e potolohang ka lebelo le phahameng. Thepa e pshatlehileng e fumana matla a kinetic ho tloha hloohong ea hamore 'me e mathela ho baffle le sieve bar ka har'a foreimi ka lebelo le phahameng. Ka nako e ts'oanang, lisebelisoa li thulana 'me li pshatleha ka makhetlo a mangata. Lisebelisoa tse nyenyane ho feta lekhalo pakeng tsa mekoallo ea sieve li ntšoa ka lekhalo, 'me lisebelisoa tse ling tse khōloanyane li hatelloa hape ka tšusumetso, ho sila le ho penya hamore ea hlooho holim'a bareng ea sieve. Thepa e extruded ho tloha lekhalo ka hamore hlooho, ka tsela eo ho fumana lakatsehang phatsa boholo sehlahiswa.

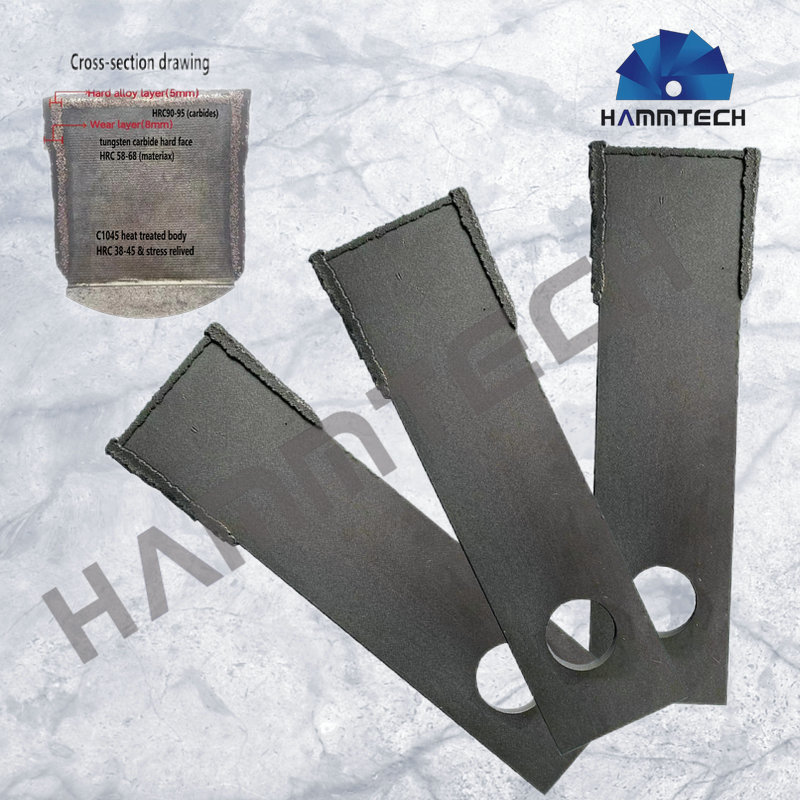

Likarolo tsa sehlahisoa:

1. Ho apara ka tlaase haholo (PPM) ho ka thibela tšilafalo ea lintho tse bonahalang.

2. Bophelo ba tšebeletso ea nako e telele le litšenyehelo tse tlaase tsa ho sebetsa ka kakaretso.

3. Hlooho ea hamore e entsoe ka thepa ea tungsten carbide, e sa senyeheng, e sa jeng, e hanyetsanang le tšusumetso, le mocheso o phahameng oa mocheso.

4. Ha ho sebetsa, lerōle le lenyenyane, lerata le tlaase, 'me ts'ebetso e boreleli.

Lihamore tsa Tungsten carbide li loketse ho senya lisebelisoa tse sa tšoaneng, ho kenyelletsa le lisebelisoa tse thata tse kang poone, lijo tsa soya, mabele, joalo-joalo. Ntle le moo, likotoana tsa hamore tsa tungsten carbide li boetse li na le ho hanyetsa acid, ho hanyetsa alkali, ho hanyetsa mocheso o tlase, ho hanyetsa mollo le thepa e 'ngoe, e loketseng maemo a fapaneng a sebetsang a thata.

Litšobotsi le Maemo a Tšebeliso ea Tungsten Carbide Hammer beater

Bothata bo phahameng: Tungsten carbide hammer beater e na le boima bo phahameng haholo mme e ka khaola le ho pshatla hoo e batlang e le lisebelisoa tse ling.

Ho hanyetsa ho roala: Ka lebaka la boima ba eona bo phahameng, tungsten carbide hammer mill beater e apara hanyenyane haholo nakong ea ts'ebetso ea ho senya 'me e loketse ho sebelisoa nako e telele.

Ho hanyetsa mocheso o phahameng: Tungsten carbide hammer beater e na le khanyetso e ntle haholo ea mocheso o phahameng mme e khona ho boloka ts'ebetso ea eona nakong ea ts'ebetso e potlakileng haholo.

Tšebeliso e pharaletseng: E loketse maemo a fapaneng a sebetsang a thata, joalo ka ho hanyetsa acid, ho hanyetsa alkali, ho hanyetsa mocheso o tlase, ho hanyetsa mollo, joalo-joalo.

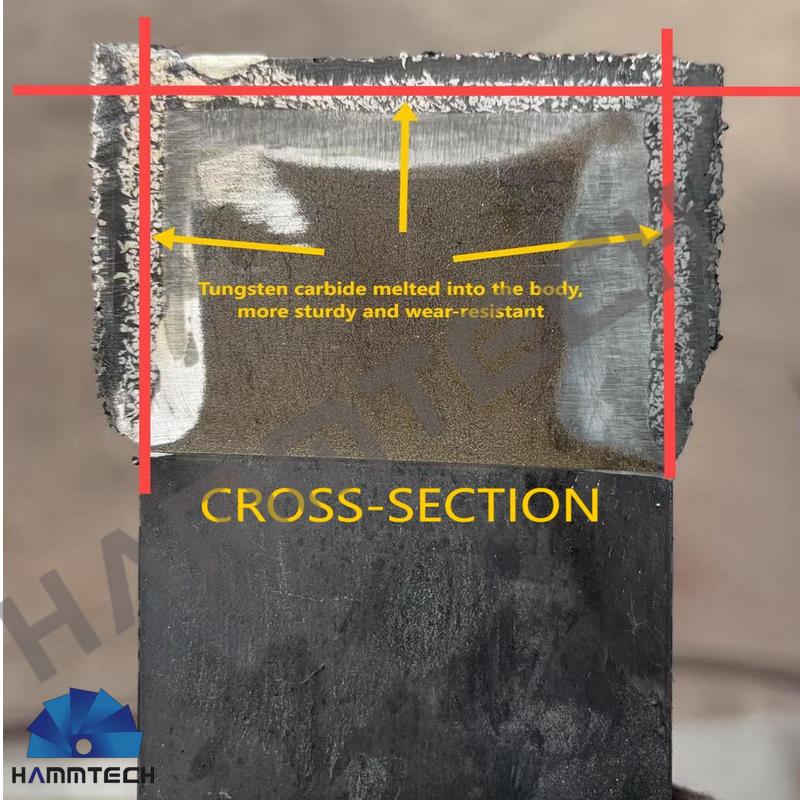

Ho ikhetha ha lihamore tsa rona tsa tungsten carbide;

Re sebelisa theknoloji e thata ea alloy particle welding, e etsang letamo la tšepe le qhibilihisang mocheso o phahameng holim'a setsi sa mosebetsi, 'me ka mokhoa o ts'oanang o romela likaroloana tse thata tsa alloy ka har'a letamo la ho qhibiliha. Ka mor'a ho pholile, likaroloana tse thata tsa alloy li etsa lera le thata la alloy. Ka lebaka la ho qhibiliha le ho tiea ha 'mele oa tšepe, ho thehoa lera le sa tsitsang,' me ha ho na litaba tse kang mapetsong a sa tšoaneng a li-welding kapa peeling.

Nako ea poso: Dec-20-2024