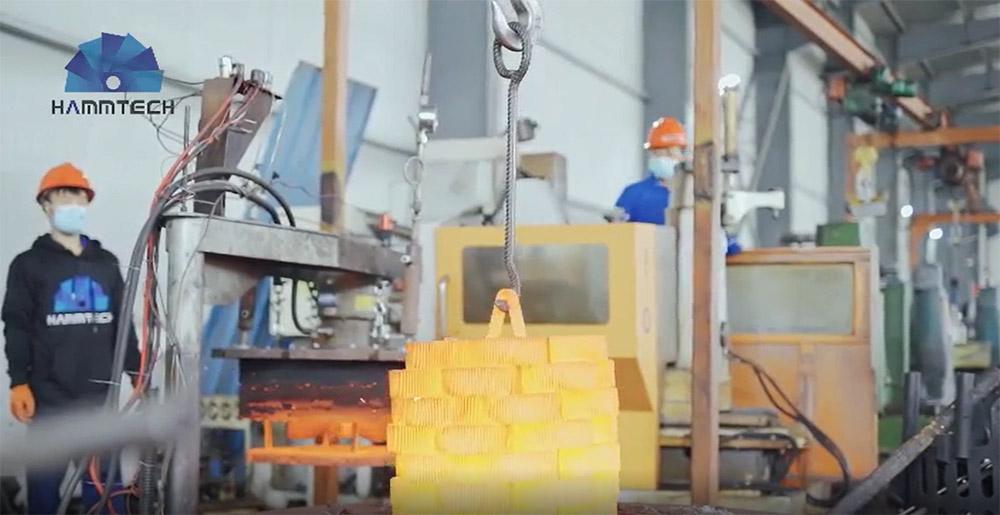

Shell ea meno a mabeli

Khetla ea leloala la pellet ke sesebelisoa sa bohlokoa sa pelletizer, seo hape ho leng bonolo ho se apara ha selikalikoe se shoa. E sebetsa haholo-holo ka ring die le flat die ho seha, ho luba, ho beha le ho petetsa lisebelisoa tse tala ho fihlela pelletizing. Likhetla tsa roller li sebelisoa haholo bakeng sa ho lokisa li-pellets tsa phepelo ea liphoofolo, li-pellets tsa mafura a biomass, jj.

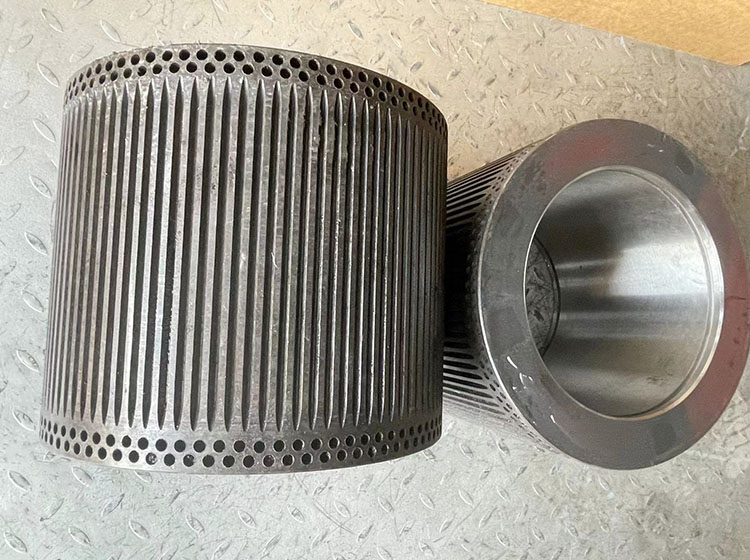

Ts'ebetsong ea granulator, e le ho etsa bonnete ba hore thepa e tala e ka hatelloa ka har'a lesoba la lefu, ho tlameha ho be le likhohlano pakeng tsa khetla ea rolara le thepa, kahoo ha ho etsoa khetla ea rolara, e tla etsoa ka mefuta e sa tšoaneng ea libaka tse thata ho thibela rolara hore e se ke ea thella. Ho na le mefuta e meraro ea libaka tse sebelisoang haholo: mofuta oa dimpled, mofuta o bulehileng, le mofuta o koetsoeng.

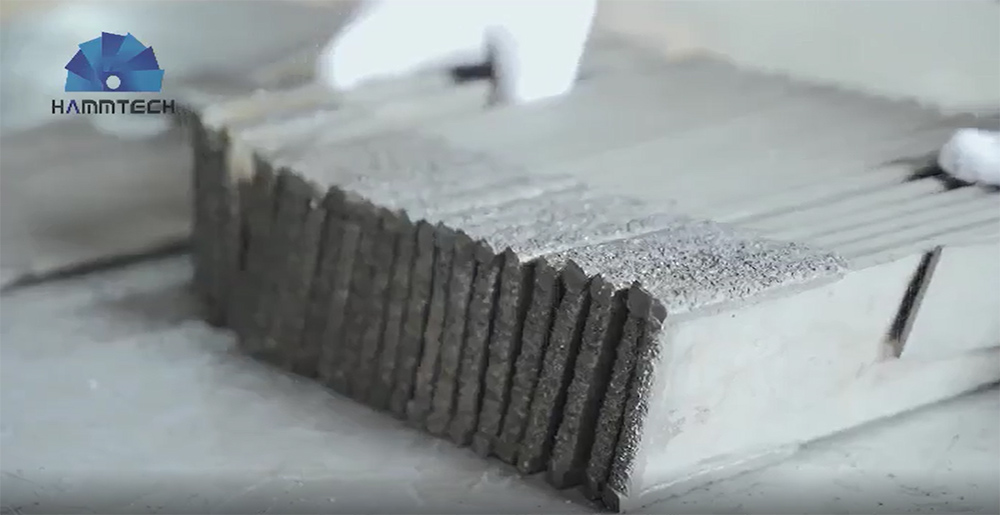

Dimpled Roller Shell

Bokaholimo ba khetla ea rolara e nang le dimple e tšoana le khekhe ea linotši e nang le masoba. Ha e ntse e sebelisoa, sekoti se tlatsitsoe ka lintho tse bonahalang, ho etsa hore ho be le khohlano holim'a coefficient e nyenyane, thepa ha e bonolo ho thellela ka thōko, ho roala ha lesale la granulator ho tšoana le ho feta, 'me bolelele ba likaroloana tse fumanoeng bo tsitsitse haholoanyane, empa ts'ebetso ea thepa ea moqolo e mpe le ho feta, ho ka 'na ha e-ba le tšusumetso ho lihlahisoa tsa lihlahisoa tse tloaelehileng, kaha mefuta e tloaelehileng ea granulator e sa tloaeleha.

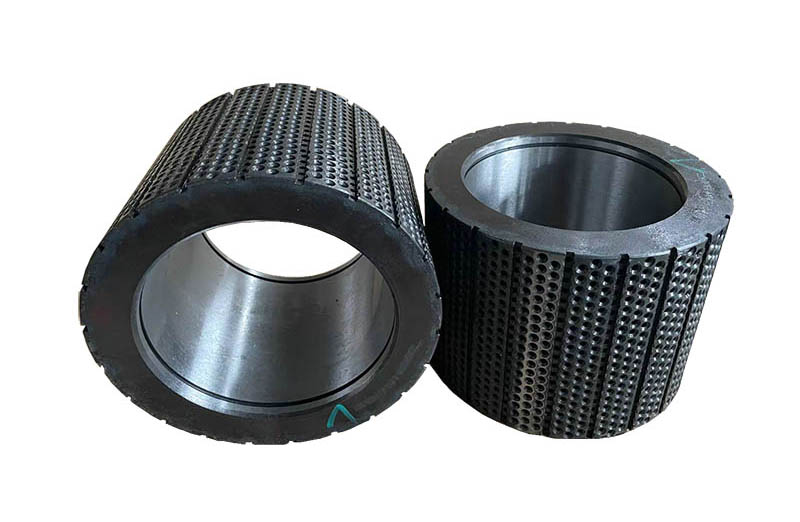

Roller Shell e bulehileng

E na le matla a matla a ho thibela ho thella le ts'ebetso e ntle ea thepa ea roll. Leha ho le joalo, ts'ebetsong ea tlhahiso, thepa e thella ka har'a groove ea meno, e ka lebisang bothateng ba ho thella ha thepa ho ea ka lehlakoreng le leng, ho fella ka phapang e itseng ea ho apara ha khetla ea rolara le lesale la shoa. Ka kakaretso, ho apara ho tebile ka lipheletsong tse peli tsa khetla rolara le lesale shoa, e leng tla lebisa ho bothata ba ho ntša lintho tse bonahalang tse ka lipheletsong tse peli tsa lesale shoa ka nako e telele, kahoo pellets entseng e khutsoanyane ho feta karolo e bohareng ea lesale shoa.

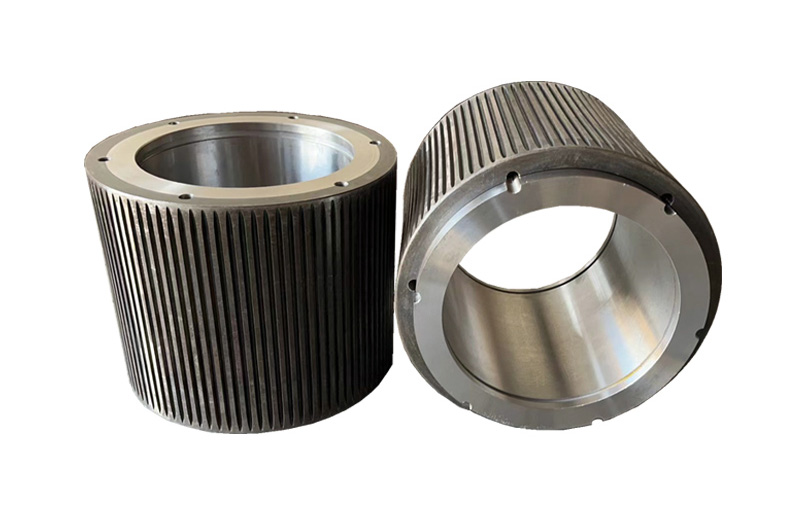

Roller Shell e koetsoeng

Lipheletso tse peli tsa mofuta ona oa likhetla tsa roller li etselitsoe hore e be mofuta o koetsoeng (mofuta oa groove o nang le meno o nang le mapheo a tiisitsoeng). Ka lebaka la likarolo tse koetsoeng ka mahlakoreng ka bobeli a groove, thepa e tala ha e thellehe habonolo mahlakoreng ka bobeli tlas'a extrusion, haholo-holo ha e sebelisoa ka extrusion ea lintho tse phelang metsing tse atisang ho thella. Sena se fokotsa ho thella hona 'me se fella ka ho ajoa ka mokhoa o lekanang, ho apara seaparo se tšoanang sa khetla ea rolara le selikalikoe, 'me ka tsela eo bolelele ba li-pellets bo tla lekana.